How Cooper Power Systems Becomes the Preferred Solution

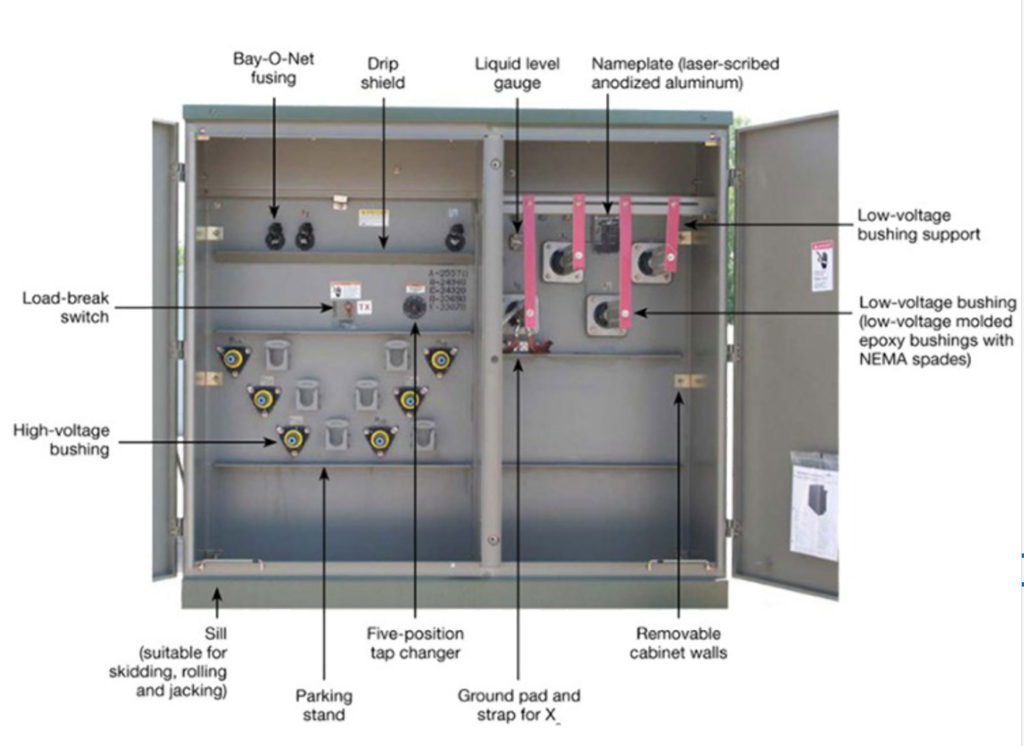

In power systems, pad-mount transformers serve as critical nodes for voltage transformation and energy distribution. Current-limiting fuses act as their primary protective devices, requiring millisecond-level interruption of overload or short-circuit currents to prevent equipment damage and fire hazards. This article compares technical parameters across three leading brands (H-J , Hi-Tech, Cooper Power Systems) in pad-mount transformer applications.

I. Synergistic Relationship Between Pad-Mount Transformers and Current-Limiting Fuses

- Functional Requirements:

Installed in surface-mounted enclosures, pad-mount transformers must endure harsh environments (extreme temperatures, humidity, vibrations). Their protective fuses must fulfill:

✅ Voltage compatibility (8.3kV to 38kV)

✅ Precision current limitation (30A-200A graded protection)

✅ Long-term reliability (10+ years maintenance-free operation) - Selection Challenges:

Variations in voltage adaptability, thermal stability, and mechanical strength across brands directly impact transformer protection efficiency and lifecycle costs.

II. Comparative Analysis of Key Parameters

Based on the provided comparison chart (covering 8.3kV to 38kV), technical characteristics are clearly differentiated:

| Brand | H-J family | Hi-Tech | Cooper Power System |

| 8.3kV Class Current Limiting Fuse | |||

| 30AMP | 9F59CBC030 | HTSS132030 | CBUC080030C100 |

| 40AMP | 9F59CBC040 | HTSS132040 | CBUC08040C100 |

| 50AMP | 9F59CBC050 | HTSS132050 | CBUC08050C100 |

| 65AMP | 9F59CBC065 | HTSS232065 | CBUC08065C100 |

| 80AMP | 9F59CBC080 | HTSS232080 | CBUC08080C100 |

| 100AMP | 9F59CBC100 | HTSS232100 | CBUC08100C100 |

| 125AMP | 9F59CBC125 | HTSS232125 | CBUC08125C100 |

| 150AMP | 9F59CBC150 | HTSS232150 | CBUC081500C100 |

| 165AMP | 9F59CBC165 | HTSS232165 | CBUC081650C100 |

| 200AMP | 9F59CBC200 | HTSS232200 | – |

| 15.5kV Class Current Limiting Fuse | |||

| 165AMP | 9F59CBD165 | HTSS242165 | CBUC15165C100 |

| 17.2kV Class Current Limiting Fuse | |||

| 30AMP | 9F59CBD030 | HTSS142030 | CBUC17030C100 |

| 40AMP | 9F59CBD040 | HTSS142040 | CBUC17040C100 |

| 50AMP | 9F59CBD050 | HTSS242050 | CBUC17050C100 |

| 65AMP | 9F59CBD065 | HTSS242065 | CBUC17065C100 |

| 80AMP | 9F59CBD080 | HTSS242080 | CBUC15080C100(15.5kV) |

| 100AMP | 9F59CBD100 | HTSS242100 | CBUC15100C100(15.5kV) |

| 125AMP | 9F59CBD125 | HTSS242125 | CBUC15125C100(15.5kV) |

| 150AMP | 9F59CBD150 | HTSS242150 | CBUC15150C100(15.5kV) |

| 25.5kV Class Current Limiting Fuse | |||

| 30AMP | 9F59CBE030 | HTSS152030(23kV) | CBUC23030C100(23kV) |

| 40AMP | 9F59CBE040 | HTSS152040(23kV) | CBUC23040C100(23kV) |

| 50AMP | 9F59CBE050 | HTSS252050(23kV) | CBUC23050C100(23kV) |

| 65AMP | 9F59CBE065 | HTSS252065(23kV) | CBUC23065C100(23kV) |

| 80AMP | 9F59CBE080 | HTSS252080(23kV) | CBUC23080C100(23kV) |

| 100AMP | 9F59CBE100 | HTSS252100(23kV) | CBUC23100C100(23kV) |

| 38kV Class Current Limiting Fuse | |||

| 65AMP | 9F59CCF065 | HTSS372065 | CBUC38050D100/CBUC38065D100 |

| 80AMP | 9F59CCF080 | HTSS372080 | CBUC38080D100 |

| 100AMP | 9F59CCF100 | HTSS372100 | CBUC38100D100 |

| 125AMP | 9F59CCF125 | HTSS372125 | CBUC38120D100 |

| 140AMP | 9F59CCF140 | HTSS372140 | CBUC38140D100 |

| 165AMP | 9F59CCF165 | HTSS372165 | CBUC38100D100x2 |

| 200AMP | 9F59CDF200 | HTSS372200 | CBUC38120D100x2 |

III. Core Advantages of Cooper Power Systems

1️⃣ Voltage Flexibility & Space Efficiency

• Dual-voltage capability: Models like CBUC15125C100 support both 15.5kV and 17.5kV systems, reducing spare part inventory

• Compact form factor: 30% smaller installation footprint compared to H-J/Hi-Tech’s composite housings

2️⃣ Dual-Layer Current Protection

• Parallel fuse configurations (e.g., CBUC38100D100x2) enable redundant 165A protection with fault-clearing speeds under 2ms

3️⃣ Extreme Environment Resistance

• Patented CermaTech® ceramic coating withstands salt spray, dust, and temperature extremes (-40℃ to 85℃)

• Compliant with IEEE C37.41 mechanical vibration standards

4️⃣ Lifecycle Cost Leadership

• No-fill design reduces maintenance frequency, achieving 15-20% lower total cost of ownership over 10 years

IV. Representative Applications

- Renewables: Solar inverter side protection against transient surges

- Industrial Grids: Multi-stage protection for steel mill rectifier transformers

- Urban Infrastructure: Space-saving deployment in underground vaults (30% volume reduction)

V. Selection Guide & Substitute Strategies

- Preferred Cooper Scenarios:

• Dual-voltage requirements or multi-stage protection needs

• Humidity >85% or chemically corrosive environments

• Selective coordination with circuit breakers - Alternative Solutions:

• Hi-Tech HTSS series as cost-effective mid-voltage backup

• H-J for laboratory-grade precision testing

Conclusion

Through technical comparison, Cooper Power Systems demonstrates significant advantages in modular architecture, voltage adaptability, and environmental resilience for pad-mount transformer protection. Contact our agency team for technical documentation and customized selection support to ensure long-term safety of your critical infrastructure.